Mercedes Gonzalez

Mercedes Gonzalez

Résumé

Education

Publications

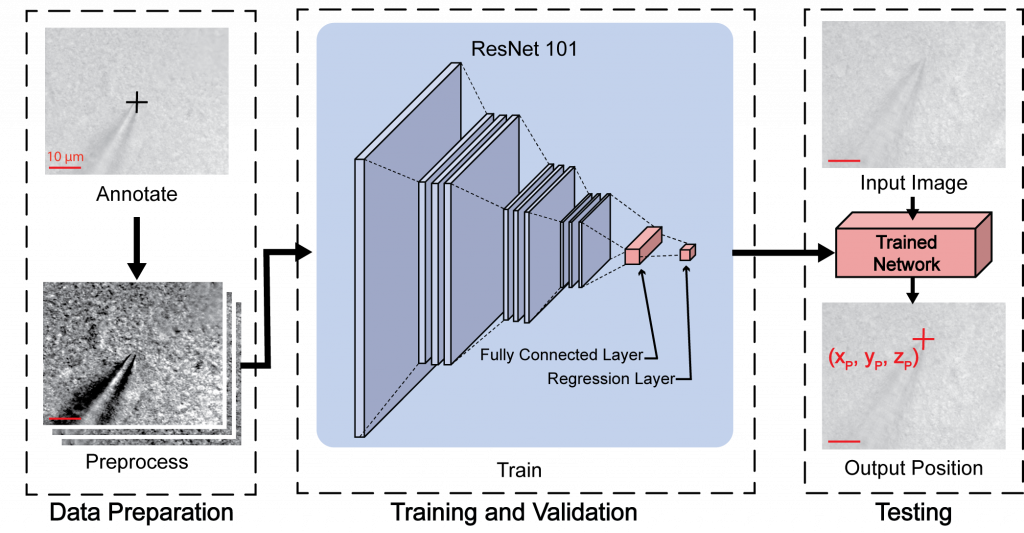

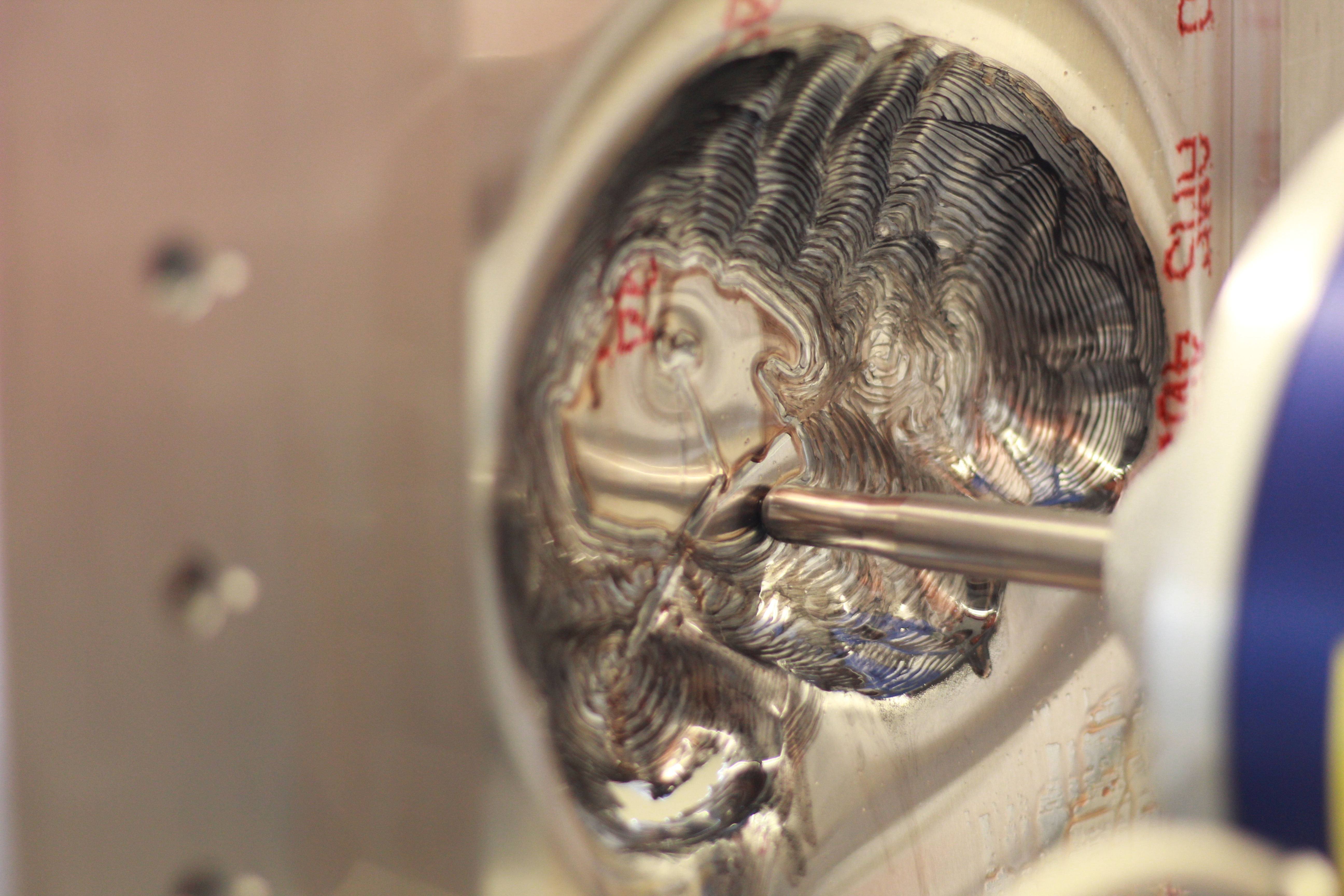

⪼ Gonzalez, M. M., Lewallen, C. F., Yip, M. C., & Forest, C. R. (2021). Machine Learning-Based Pipette Positional Correction for Automatic Patch Clamp In Vitro. ENeuro, 8 (August), 1–8. doi: https://doi.org/10.1523/ENEURO.0051-21.2021 [PDF]

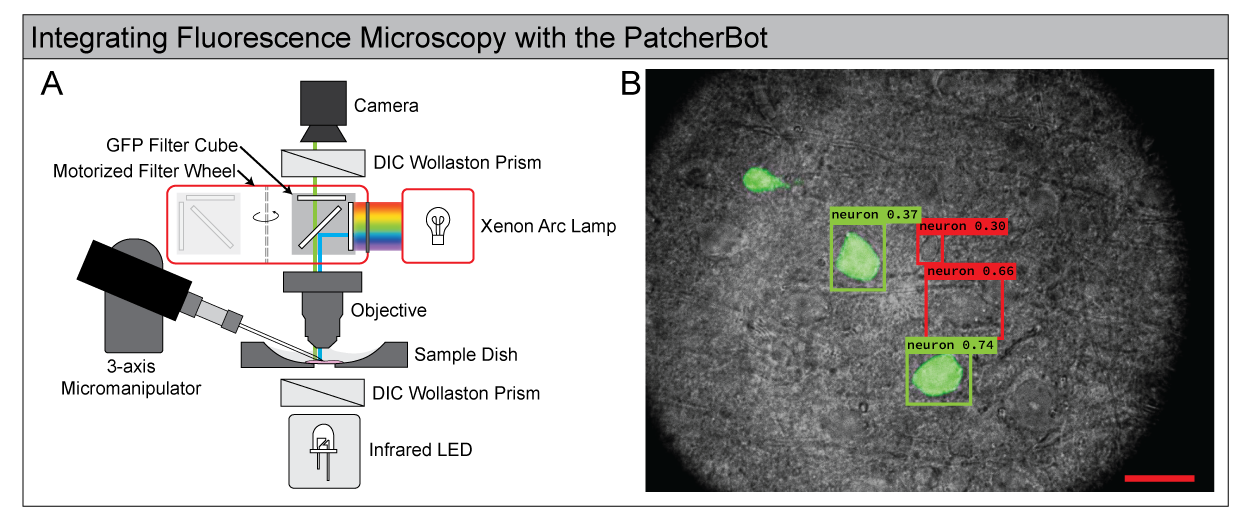

⪼ Yip, M.C., Gonzalez, M.M., Valenta, C.R., Rowan, M.J.M., Forest, C.R. Deep learning-based real-time detection of neurons in brain slices for in vitro physiology. Sci Rep 11, 6065 (2021). https://doi.org/10.1038/s41598-021-85695-4 [PDF]

⪼ Landry, C. R., Yip, M. C., Kolb, I., Stoy, W. M., Gonzalez, M. M. and Forest, C. R. (2021). Method for Rapid Enzymatic Cleaning for Reuse of Patch Clamp Pipettes: Increasing Throughput by Eliminating Manual Pipette Replacement between Patch Clamp Attempts. Bio-protocol 11(14): e4085. DOI: 10.21769/BioProtoc.4085. [PDF]

Experience

Graduate Research Assistant, Georgia Institute of Technology